The Ultimate Overview to Increasing Lifespan: Undercarriage Parts Maintenance Made Easy

The Ultimate Overview to Increasing Lifespan: Undercarriage Parts Maintenance Made Easy

Blog Article

Discover Undercarriage Components for Heavy Machinery

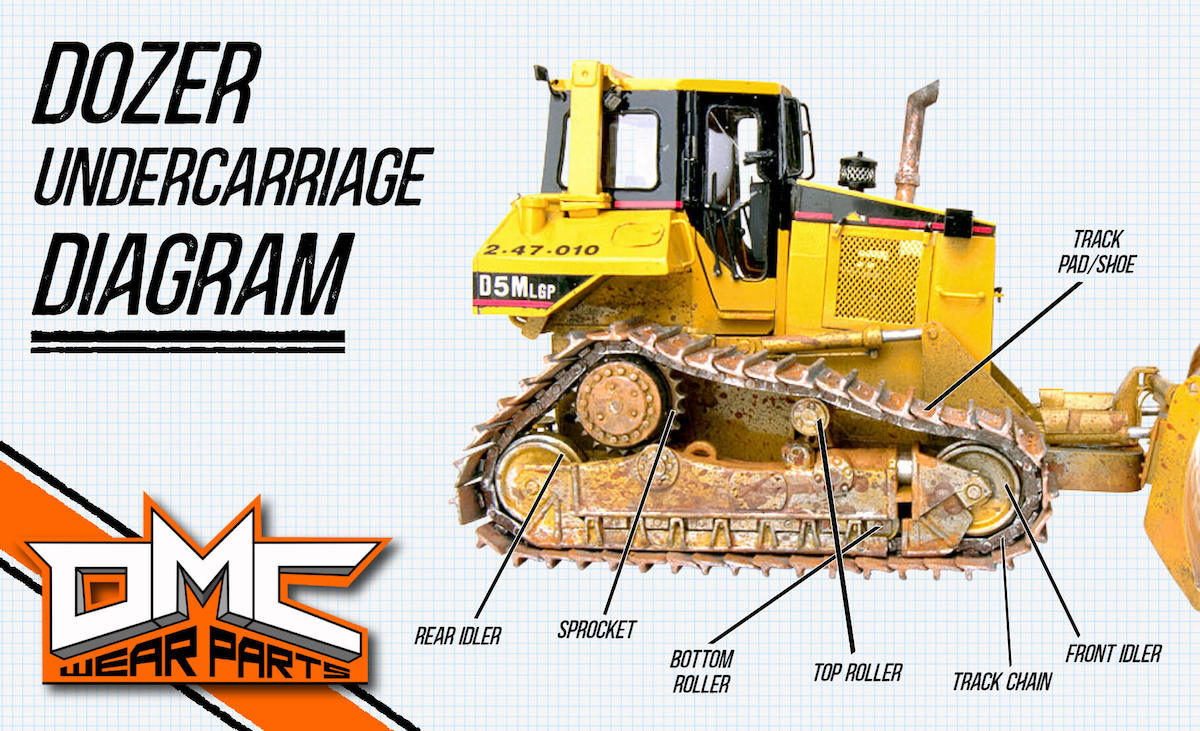

Understanding the intricacies of undercarriage components is necessary for the ideal performance and long life of hefty equipment. From track shoes to idlers, rollers, and gears, each element plays an essential function in the functionality of the devices.

Relevance of Undercarriage Parts

The undercarriage parts of heavy machinery play an important duty in ensuring the general performance and long life of the devices. These elements, consisting of tracks, rollers, gears, idlers, and chains, form the foundation upon which the device operates. A properly maintained undercarriage not only supplies security and assistance to the hefty machinery yet additionally adds considerably to its operational efficiency and efficiency.

Among the crucial advantages of investing in high-grade undercarriage components is the decrease of downtime and maintenance expenses. By using resilient elements that can endure the roughness of heavy-duty applications, operators can reduce the demand for constant repair work and substitutes, hence maximizing the device's uptime and general life-span.

Furthermore, correctly functioning undercarriage parts guarantee optimal weight grip, circulation, and ability to move, permitting the hefty machinery to run smoothly even in challenging surfaces. This dependability is important for industries such as building, mining, and farming, where equipment efficiency directly affects project timelines and profitability. Finally, the importance of undercarriage components can not be overstated in maintaining the effectiveness and durability of hefty machinery.

Kinds of Track Shoes

When thinking about the different types of track shoes for hefty machinery, it is crucial to assess their style and performance in connection with certain operational requirements. Track shoes are crucial elements of the undercarriage system, giving stability, traction, and weight distribution for heavy machinery such as excavators, excavators, and spider cranes.

The most common sorts of track shoes consist of:

** Grouser Shoes **: Featuring raised metal bars (grousers) along the shoe's surface area, these track footwear supply boosted traction in challenging surfaces like mud, snow, and loosened crushed rock. undercarriage parts.

** Double Grouser Shoes **: Similar to grouser footwear but with an extra set of grousers, these track shoes provide also higher traction and stability, making them ideal for exceptionally rough terrains.

** Three-way Grouser Shoes **: With 3 sets of grousers, these track footwear provide optimal grip and stability, making them suitable for the most demanding conditions.

Picking the ideal kind of track shoe is essential for maximizing the efficiency and long life of hefty machinery while making certain security and efficiency throughout procedures.

Feature of Rollers and Idlers

Rollers and idlers play essential functions in supporting and directing the track shoes of hefty machinery throughout procedure. Rollers are cylindrical parts that support the weight of the devices and guarantee smooth motion along the surface. They aid distribute the machine's weight uniformly, minimizing wear on the track shoes and lessening vibrations. Idlers, on the other hand, guide the track chain and aid maintain appropriate tension. By stopping excessive slack or rigidity in the tracks, idlers add to the general security and efficiency of the machinery (undercarriage parts).

Furthermore, idlers and rollers work with each other to keep the track footwear abreast, stopping them from slipping or thwarting off during operation. Effectively functioning idlers and rollers are critical for guaranteeing the long life of the undercarriage system and optimizing the device's performance. Regular maintenance and assessment of these parts are necessary to recognize any kind of indications of wear or damage beforehand, preventing pricey repairs and downtime in the future.

Duty of Sprockets in Equipment

Maintenance Tips for Undercarriage Parts

Reliable upkeep of undercarriage elements is crucial for making certain the long life and optimal efficiency of heavy machinery. Routine evaluation of undercarriage parts such as track chains, rollers, idlers, gears, and track footwear is essential to stop costly repairs and unforeseen break downs. One crucial upkeep idea is to keep the undercarriage clean from debris, mud, and various other impurities that can increase wear and rust. It is also vital to ensure correct track stress to avoid early wear on parts. Oiling the undercarriage components at recommended intervals assists to decrease friction and prolong the life expectancy of the elements. Checking for any type of uncommon noises, vibrations, or changes in device performance can show potential problems with the undercarriage that call for immediate focus. By following these upkeep ideas carefully, hefty equipment operators can reduce downtime, reduce operating expenses, and make best use of the efficiency of their tools.

Conclusion

To conclude, the undercarriage components of my explanation heavy equipment play an essential duty in ensuring the smooth functioning and durability of the tools. Comprehending go the relevance of track shoes, rollers, idlers, and sprockets, along with applying proper upkeep techniques, can significantly affect the total performance and efficiency of the equipment (undercarriage parts). Regular inspection and prompt replacement of damaged components are important in making the most of the life expectancy and performance of hefty machinery

Rollers and idlers play essential functions in sustaining and assisting the track footwear of heavy equipment throughout operation.In heavy equipment, gears serve a vital function in moving power from the engine to the tracks, enabling the tools to move successfully and efficiently. These elements are connected to the axles or final drives of the machinery and job in combination with the tracks to thrust the tools ahead or backwards. Regular evaluation of undercarriage components such as track chains, rollers, idlers, sprockets, and track footwear is essential to stop unanticipated breakdowns and expensive repair services. Recognizing the relevance of track footwear, rollers, idlers, and gears, as well as carrying out correct upkeep methods, can substantially impact the general performance and effectiveness of the equipment.

Report this page